- This topic is empty.

-

AuthorPosts

-

25/06/2025 at 14:33 #7301

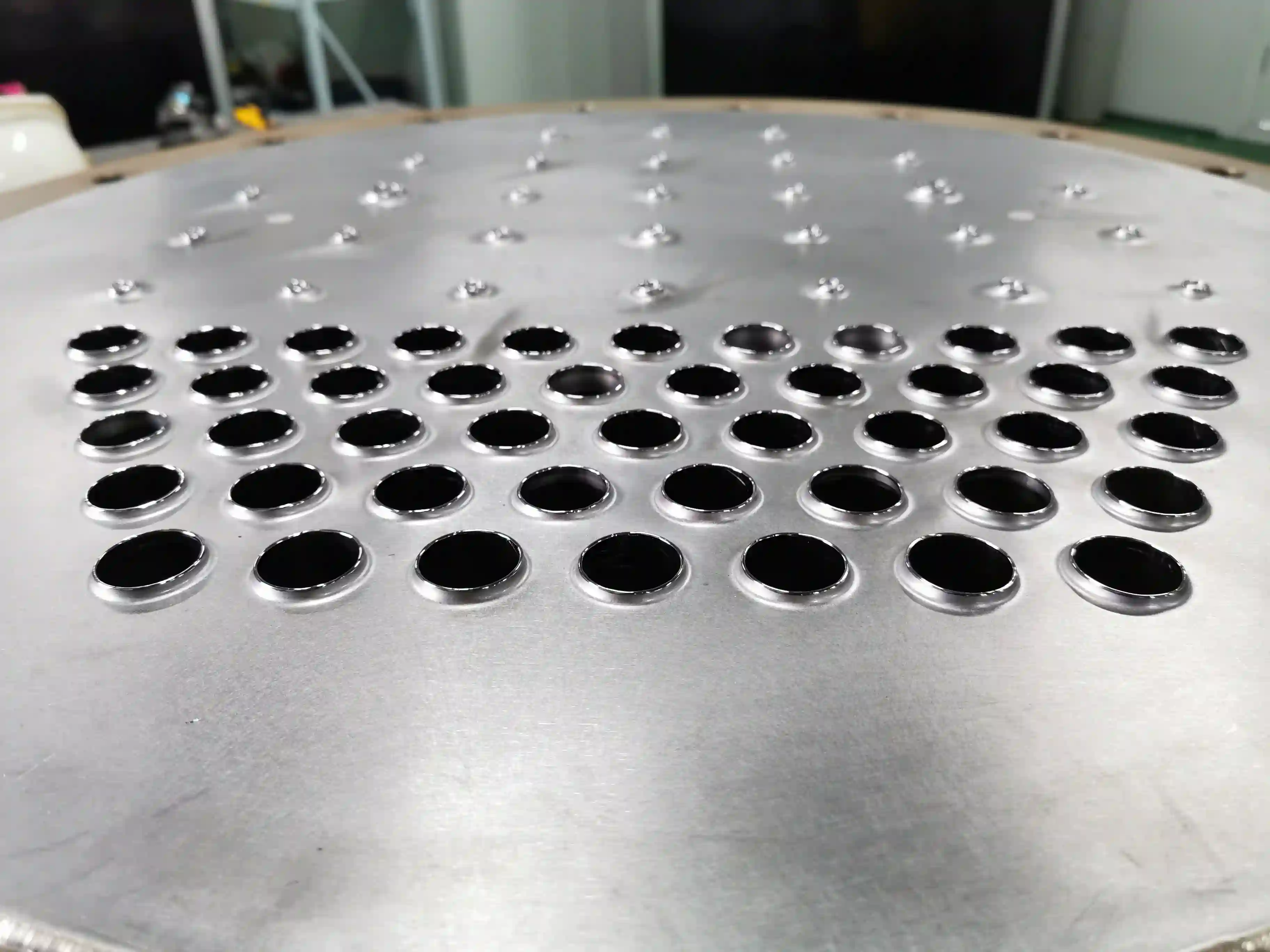

In contemporary industrial processes, ensuring optimal performance and durability of equipment under harsh operational conditions is crucial. One remarkable solution enhancing the resilience and functionality of heat exchangers is the tantalum bayonet heater tube sheet liner. Renowned for its exceptional corrosion resistance, thermal stability, and mechanical integrity, this liner significantly improves equipment longevity and efficiency. This article Qiwei explores the core characteristics of tantalum bayonet heater tube sheet liners.

What are Tantalum Bayonet Heater Tube Sheet Liners?

Tantalum bayonet heater tube sheet liners are specifically crafted protective inserts designed for installation in heat exchanger tube sheets, protecting the tube sheet and associated bayonet heaters from aggressive corrosive environments. Tantalum, a rare transition metal, is utilized due to its superior resistance to a wide range of corrosive chemicals such as hydrochloric acid, sulfuric acid, chlorine-based compounds, and other aggressive substances.

These liners fit seamlessly into existing heat exchanger structures, effectively isolating the vulnerable tube sheets and heater components from chemical corrosion and mechanical wear. The deployment of tantalum liners is vital for industries requiring stringent protection standards, particularly in chemical, pharmaceutical, and petrochemical sectors.

Core Characteristics of Tantalum Bayonet Heater Tube Sheet Liners

The tantalum bayonet heater tube sheet liner is a critical component in industrial heating systems, especially in environments involving highly corrosive chemicals and elevated temperatures. Its remarkable performance and long-term reliability are attributed to the superior properties of tantalum, a metal known for its durability and resistance in extreme operating conditions.

1. Outstanding Corrosion Resistance

One of the most valued features of the tantalum bayonet heater tube sheet liner is its exceptional resistance to chemical corrosion. Tantalum naturally forms a stable oxide film on its surface, providing an impenetrable barrier against aggressive acids such as hydrochloric, nitric, and sulfuric acid. This property allows the liner to perform reliably even in the harshest process environments, making it an ideal choice for chemical processing plants. The longevity and resistance of the tantalum bayonet heater tube sheet liner significantly reduce maintenance requirements and help prevent costly system failures.

2. Exceptional Thermal Stability

The tantalum bayonet heater tube sheet liner also excels in maintaining mechanical integrity under high thermal stress. Industrial heating applications often involve rapid temperature fluctuations, and materials that cannot withstand these changes may suffer from thermal fatigue or failure. Tantalum’s high melting point and thermal inertia ensure that the liner retains its structural stability and performance over time, safeguarding the operational consistency of the heating system.

3. High Thermal Conductivity

Another core advantage of using a tantalum bayonet heater tube sheet liner is its excellent thermal conductivity. This property ensures rapid and uniform heat transfer across the liner surface, which is essential for efficient heat exchanger operation. With improved heat distribution, the system operates more efficiently, with reduced risk of localized overheating or energy waste. This efficiency contributes to lower operational costs and better overall system performance.

4. Superior Mechanical Strength and Structural Integrity

In addition to chemical and thermal resilience, the tantalum bayonet heater tube sheet liner offers high mechanical strength. It resists deformation, cracking, and fatigue even under pressure surges, flow-induced vibrations, and mechanical stress. This robustness is crucial in dynamic process environments, where equipment reliability is vital for uninterrupted operation. By reinforcing the tube sheet, the tantalum liner ensures long-lasting structural performance, even under continuous heavy-duty usage.

5. Excellent Integration and Material Compatibility

The tantalum bayonet heater tube sheet liner is not only effective on its own but also highly compatible with other base materials such as stainless steel or carbon steel. Through methods such as explosion bonding or diffusion welding, tantalum liners can be securely applied to other metals, combining the corrosion resistance of tantalum with the structural support of lower-cost substrates. This compatibility offers manufacturers both flexibility in system design and economic efficiency.

Tantalum bayonet heater tube sheet liners represent an essential advancement in protecting and optimizing industrial heat exchange systems. Offering unmatched resistance to corrosion, excellent thermal stability, and structural robustness, these liners significantly enhance operational reliability and economic efficiency across numerous industrial applications. Through precise installation, diligent maintenance, and sustainable practices, industries can fully harness the potential of tantalum bayonet heater tube sheet liners, securing sustained industrial performance, safety, and efficiency.

https://www.tnztn.com/Tantalum-Bayonet-Heater-Tube-sheet-liner.html

http://www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.

Google hit with record EU fine over Shopping service

Google hit with record EU fine over Shopping service  Business booming for giant cargo planes

Business booming for giant cargo planes  Trump-Putin: The understandable story

Trump-Putin: The understandable story