- This topic is empty.

-

AuthorPosts

-

17/07/2025 at 18:13 #7527

In today’s competitive manufacturing landscape, choosing the right gear hobbing machine can make a significant difference in your productivity, machining accuracy, and long-term operational costs. Whether you're producing gears for automotive, motorcycle, gearbox, timing pulley, or pump applications, a medium CNC gear hobbing machine offers the perfect balance between flexibility and performance. But how do you select the right one for your workshop?

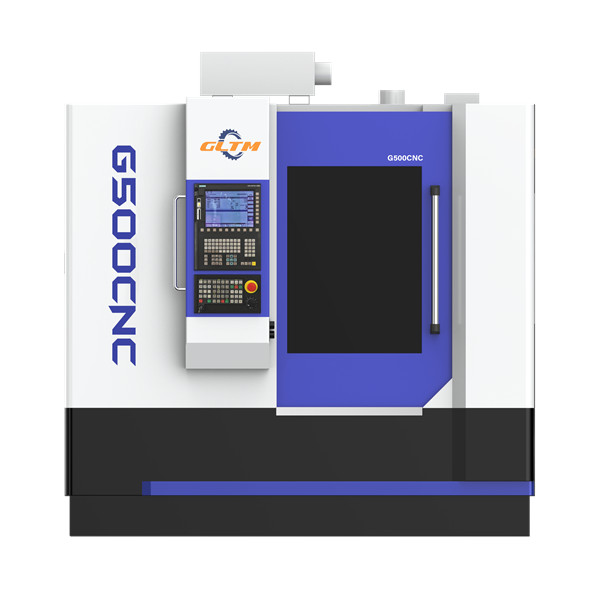

Let’s explore the key considerations—and why manufacturers around the world trust GLT Machinery (GLTM/GLT), a leading CNC gear hobbing machine manufacturer from China, for high-performance solutions.

1. Understand Your Production Needs

Before choosing a machine, clearly define your production requirements:

-

What gear sizes and module ranges will you be cutting?

-

What materials will you be machining?

-

What is your average batch size?

-

What level of precision and surface finish do your end products require?

A medium CNC gear hobbing machine is ideal for workshops with mid-sized gears and moderate-to-high production volumes, where a balance of speed, rigidity, and cost-efficiency is essential.

2. Look for High Rigidity and Stability

Machining gears, especially under demanding conditions, requires a machine that is mechanically robust. Machines from GLT Machinery (GLTM/GLT) are designed with high rigidity in mind, ensuring stable performance even during long production cycles or when working with tough materials. A rigid structure minimizes vibration and enhances gear profile accuracy, especially critical in automotive and industrial applications.

3. Prioritize Efficiency and Automation

In today’s smart workshops, time is money. Medium CNC gear hobbing machines should offer:

-

High-speed cutting capabilities

-

Automatic loading/unloading systems

-

Tool life management

-

Real-time monitoring features

GLT’s CNC gear hobbing machines are known for their high efficiency, helping manufacturers boost output without sacrificing quality. The advanced CNC system enables seamless integration with digital manufacturing processes and improves operational throughput.

4. Assess Reliability and Support

Investing in a gear hobbing machine is a long-term decision. Reliability matters, not just in machine uptime but also in the availability of after-sales support and spare parts. GLT Machinery has successfully provided gear machining solutions to customers across automotive, motorcycle, gearbox, timing pulley, and pump industries, earning a strong reputation for high reliability and responsive technical service.

5. Customization and Industry Expertise

Every workshop has its own workflow, tooling preferences, and floor layout. GLT Machinery offers tailored gear hobbing solutions to meet specific customer needs. Whether you require special workholding, unique automation setups, or integration with other production lines, GLT’s engineering team can help you customize the perfect system.

6. Consider Digital Integration

As Industry 4.0 becomes more prevalent, your gear hobbing machine should be future-ready. Look for:

-

CNC systems with remote monitoring

-

Predictive maintenance features

-

Compatibility with MES/ERP systems

GLT’s machines are engineered to support digital transformation through intelligent design and connectivity features, making them a strategic asset in modern smart manufacturing environments.

Final Thoughts

Choosing the right medium CNC gear hobbing machine goes beyond just comparing specs—it’s about finding a reliable, efficient, and scalable solution that fits your long-term production goals. With its commitment to high rigidity, high efficiency, and high reliability, GLT Machinery (GLTM/GLT) stands out as a trusted partner for manufacturers looking to upgrade or expand their gear machining capabilities.

Whether you're in the automotive sector or supplying precision parts for gearboxes and pumps, investing in the right machine today can drive your competitive edge for years to come.

http://www.gltmachinery.com

Wuxi General Machinery Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.

Google hit with record EU fine over Shopping service

Google hit with record EU fine over Shopping service  Business booming for giant cargo planes

Business booming for giant cargo planes  Trump-Putin: The understandable story

Trump-Putin: The understandable story