- This topic is empty.

-

AuthorPosts

-

24/12/2025 at 10:07 #8427

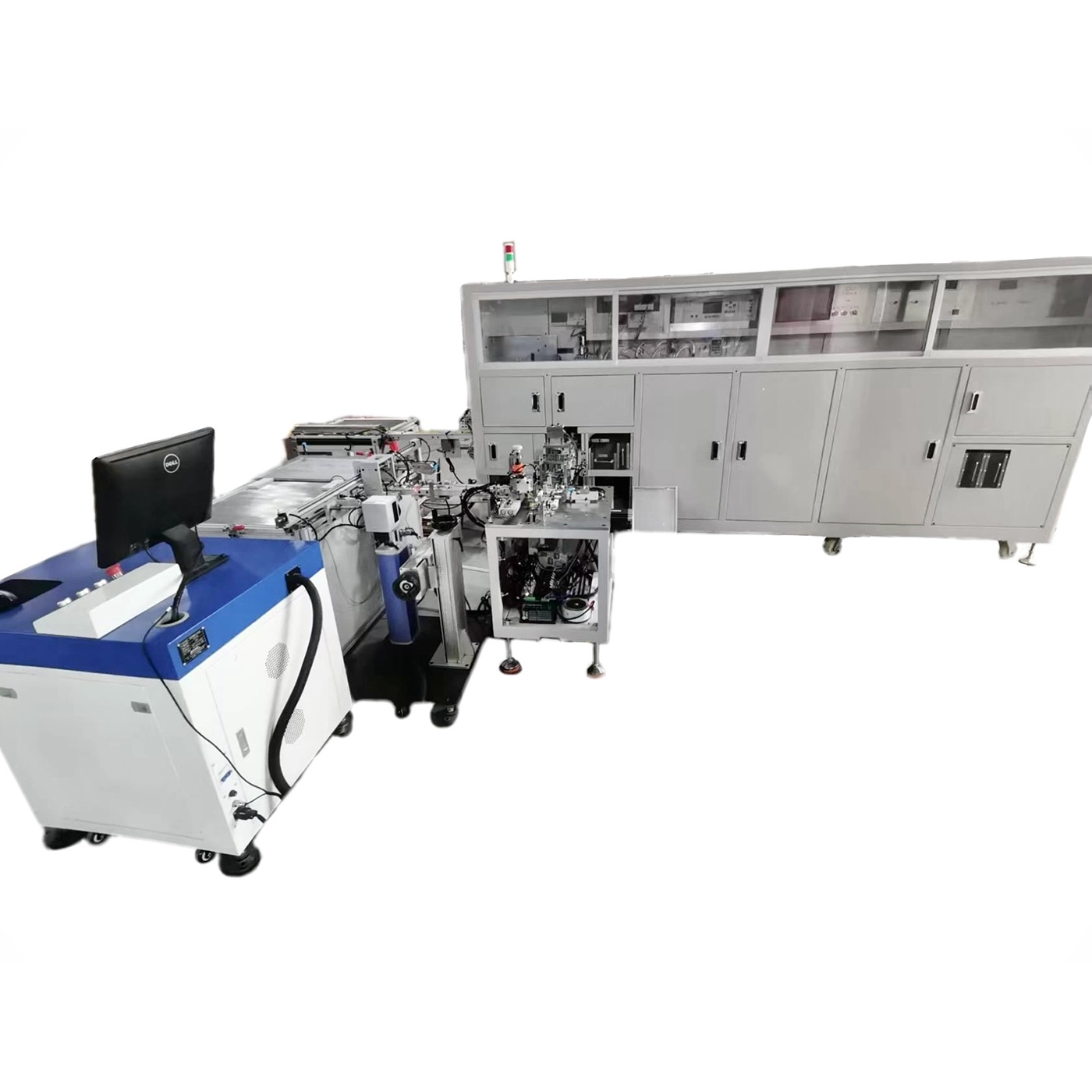

In capacitor manufacturing, precision, efficiency, and consistency are critical to ensuring the performance and reliability of electronic components. Lead trimming test machines play a vital role in addressing one of the most common issues in production lines: feeding errors. Dongguan Chuanxiang Electronic Equipment Co., Ltd., a leading high-tech enterprise specializing in intelligent testing solutions, has developed advanced lead trimming and testing systems that effectively reduce errors while improving production stability for capacitors.

Addressing Feeding Inaccuracies and Production Inefficiencies

One of the major challenges in traditional capacitor manufacturing is the wear and stretching of chain mechanisms over time, which leads to inaccurate positioning and unstable feeding. These issues can cause production delays, component misalignment, and increased scrap rates. Chuanxiang Electronics’ lead trimming test machines are specifically designed to overcome these limitations. By adopting precision transmission systems with minimal noise and light mechanical load, the machines ensure smooth and accurate handling of capacitors throughout the trimming process.

The elimination of chain oiling also reduces contamination, preventing dirt accumulation that can affect component quality and test accuracy. This not only improves product yield but also enhances operational safety and maintenance efficiency.

High-Precision Lead Trimming and Testing

Chuanxiang’s machines combine high-precision trimming mechanisms with intelligent testing functions. Each capacitor lead is trimmed to exact specifications, ensuring proper length and alignment before further assembly or packaging. The integrated test systems simultaneously verify electrical and mechanical parameters, identifying defective components early in the production line. This dual-function approach minimizes downstream errors and reduces the need for manual inspection.

By providing consistent and reliable lead trimming, the system contributes to overall manufacturing accuracy, which is especially critical for thin-film metallized capacitors widely used in 3C electronics, automotive electronics, and other high-reliability applications.

Enhancing Production Efficiency

Automated lead trimming test machines significantly improve production throughput by minimizing human intervention and manual handling. With a stable feeding system and precise trimming capability, these machines can maintain high-speed operations without compromising quality. According to industry research, automated lead trimming and testing systems can increase line efficiency by up to 30% while reducing component rejection rates by 15-20%, highlighting their value in modern capacitor manufacturing.

Furthermore, the reduction in mechanical noise and friction ensures smoother operations and lower maintenance requirements. This enables manufacturers to achieve continuous 24/7 production with fewer disruptions.

Integration with Smart Manufacturing Practices

Chuanxiang Electronics emphasizes customer-oriented customization and integration. Lead trimming test machines can be tailored to match specific capacitor sizes, lead configurations, and production line layouts. Integration with existing automated feeding systems, conveyors, and sorting mechanisms allows seamless implementation into smart manufacturing environments. This adaptability ensures that capacitor manufacturers can scale production efficiently while maintaining consistent product quality.

Quality Assurance and Reliability

Reliable lead trimming and testing are critical for meeting industry standards and customer expectations. Chuanxiang Electronics’ machines undergo rigorous quality control and leverage patented technologies and software solutions to ensure precision and consistency. The machines’ lightweight and smooth transmission systems not only reduce wear and tear but also provide repeatable accuracy for thousands of components in high-volume production lines.

By reducing feeding errors, these machines minimize waste and improve product reliability, which is particularly important for capacitors used in automotive electronics, medical devices, and industrial applications where component failure is not an option.

Industry Applications

Chuanxiang’s lead trimming test machines are widely applicable across multiple industries:

-

3C Electronics: Ensures high-precision leads for capacitors used in consumer electronics, improving device reliability and lifespan.

-

Automotive Electronics: Supports production of capacitors that meet stringent automotive standards, reducing failure risks in safety-critical applications.

-

Industrial Components: Guarantees uniformity in capacitors used in heavy machinery and industrial automation systems.

The versatility and precision of these machines allow manufacturers to maintain consistent quality across different capacitor types, sizes, and production volumes.

FAQ

Q1: How does a lead trimming test machine reduce feeding errors?

A1: By replacing traditional chain-driven feeding systems with precision transmission mechanisms, the machine ensures accurate positioning, smooth handling, and minimal mechanical wear, preventing misfeeds.Q2: Can the machine handle high-speed production lines?

A2: Yes, the system is designed for continuous, high-speed operations, maintaining precision while increasing throughput and reducing human intervention.Q3: Does the machine reduce maintenance issues caused by chain oiling?

A3: Absolutely. The advanced transmission system eliminates chain oiling, reducing dirt accumulation and mechanical wear, which lowers maintenance needs.Q4: Is this machine suitable for different capacitor types?

A4: Yes, Chuanxiang’s machines can be customized for various capacitor sizes, lead types, and production requirements, ensuring broad applicability.Q5: How does lead trimming testing improve overall product quality?

A5: By trimming leads to exact specifications and simultaneously testing electrical and mechanical parameters, the machine reduces defects and ensures consistent product performance.

By combining precision lead trimming, automated testing, and intelligent feeding systems, Chuanxiang Electronics’ lead trimming test machines effectively reduce feeding errors, enhance production efficiency, and ensure high-quality capacitor manufacturing. These solutions are essential for manufacturers aiming to achieve consistent performance, lower scrap rates, and optimize production workflows.

http://www.cxdzsb.com

Dongguan Chuanxiang Electronic Equipment Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.

Google hit with record EU fine over Shopping service

Google hit with record EU fine over Shopping service  Business booming for giant cargo planes

Business booming for giant cargo planes  Trump-Putin: The understandable story

Trump-Putin: The understandable story