- This topic is empty.

-

AuthorPosts

-

23/01/2026 at 18:37 #8542

In the petroleum and petrochemical industry, lightning is not just a natural phenomenon—it is a major operational risk. Refineries, tank farms, pipelines, offshore platforms, and substations handle flammable materials, high-value equipment, and complex electrical systems. A single lightning strike can trigger fires, explosions, power outages, data loss, and prolonged downtime. That is why petroleum petrochemical lightning protection has evolved from traditional grounding rods and surge protectors into intelligent, data-driven, and predictive protection systems. Sunlightweld, a professional earthing materials, grounding products, earthing system, and lightning protection supplier, manufacturer, and factory, is leading this transformation with smart grounding monitoring systems, intelligent grounding and lightning protection platforms, and advanced lightning warning devices designed specifically for high-risk industrial environments.

Lightning Challenges Unique to the Petroleum and Petrochemical Industry

The petroleum and petrochemical industry faces unique and severe challenges in petroleum petrochemical lightning protection. Extensive outdoor metal structures—such as storage tanks, flare stacks, pipelines, and loading arms—significantly increase the likelihood of lightning strikes, and when combined with flammable and explosive materials, the consequences of failure can be catastrophic. Over time, grounding systems degrade due to soil corrosion, moisture variation, chemical exposure, and conductor aging, while traditional inspection methods often fail to reveal these hidden risks. Meanwhile, increasing demands for continuous operation mean that unplanned downtime caused by lightning or grounding failures can lead to substantial production losses, regulatory penalties, and reputational damage. In this context, intelligent petroleum petrochemical lightning protection solutions are no longer just compliance tools, but strategic investments essential for safe, reliable, and uninterrupted operations.

Petroleum Petrochemical Lightning Protection in Industrial Operations

Beyond technical design, petroleum petrochemical lightning protection has become a fundamental requirement for safe operations, regulatory compliance, and long-term asset management. In high-risk environments where flammable substances are present, lightning-related failures can lead not only to equipment damage but also to personnel injuries, environmental incidents, and regulatory penalties. As a result, lightning protection is increasingly evaluated as part of overall operational risk control rather than an isolated engineering task.

For petroleum and petrochemical operators, maintaining continuous production is critical. Lightning-induced grounding failures or surge events can force emergency shutdowns, disrupt process control systems, and delay restart procedures. Effective petroleum petrochemical lightning protection helps reduce unplanned downtime by ensuring grounding integrity and electrical safety even during severe weather conditions.

Compliance requirements further elevate the importance of lightning protection. Many international safety standards and industrial regulations require documented lightning risk assessments, grounding performance verification, and ongoing maintenance records for hazardous locations. A structured petroleum petrochemical lightning protection approach supports these obligations by providing measurable safety performance, traceable inspection data, and auditable maintenance evidence.

From a workforce safety perspective, reliable lightning protection reduces step and touch voltage hazards in exposed areas such as tank roofs, loading zones, and outdoor substations. This contributes to safer working conditions and strengthens an organization's overall safety culture.

In this context, petroleum petrochemical lightning protection is best understood as a long-term operational investment—one that protects people, preserves assets, and supports stable, compliant, and resilient industrial operations.

Sunlightweld Petroleum Petrochemical Lightning Protection Products

Sunlightweld offers a dedicated portfolio of petroleum petrochemical lightning protection products engineered for high-risk industrial environments such as oil refineries, petrochemical plants, tank farms, and pipeline systems. These solutions combine intelligent monitoring, digital management, and early-warning technologies to help operators improve safety performance and reduce lightning-related operational risks.

Smart Grounding Monitoring System

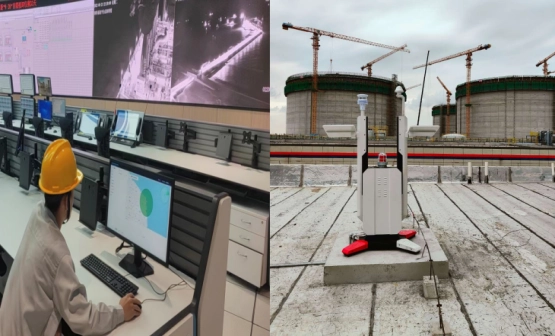

The Sunlightweld smart grounding monitoring system is a key component of modern petroleum petrochemical lightning protection strategies. It continuously monitors the actual condition of grounding systems that protect critical electrical equipment and hazardous process areas.

By providing real-time visibility into grounding performance, the system enables early detection of abnormal conditions that could weaken lightning protection effectiveness. This approach helps petrochemical operators maintain grounding reliability without relying solely on periodic manual testing.

Smart Grounding and Lightning Protection Platform

Designed to support large-scale industrial safety management, the smart grounding and lightning protection platform serves as an intelligent control layer for petroleum petrochemical lightning protection systems. Through IoT connectivity and cloud-based data processing, it centralizes grounding and lightning-related information from multiple sites into a unified interface.

The platform supports risk assessment, data analysis, and coordinated response, making it suitable for petrochemical enterprises that require consistent lightning protection management across complex facilities.

Lightning Warning Device

The Sunlightweld lightning warning device enhances petroleum petrochemical lightning protection by providing localized, short-term lightning alerts. It monitors changes in the atmospheric electric field and issues early warnings before lightning activity occurs nearby.

This device is particularly useful for petrochemical sites with outdoor operations, exposed storage tanks, and open loading areas, where advance notice allows personnel to implement preventive safety measures and reduce potential losses.

Complete Supply Capability

Beyond intelligent systems, Sunlightweld is an experienced earthing materials and lightning protection supplier, manufacturer, and factory, offering grounding conductors, electrodes, and connection solutions that form the physical foundation of petroleum petrochemical lightning protection systems.

Supported by China's strong manufacturing ecosystem, Sunlightweld delivers competitive cost advantages and stable supply capacity, helping partners achieve higher project efficiency and improved commercial returns in global markets.

Conclusion

Lightning will always be a natural threat—but its impact on petroleum and petrochemical facilities can be intelligently managed. With smart grounding monitoring systems, integrated protection platforms, and advanced lightning warning devices, Sunlightweld petroleum petrochemical lightning protection products provide a safer, smarter, and more profitable path forward. For companies seeking reliable protection and global competitiveness, Sunlightweld stands ready as a long-term partner.

https://www.sltup.com/petroleum-petrochemical-lightning-protection-sunlightweld-smart-solutions.html

https://www.sltup.com/Lightning-Protection-System

http://www.sltup.com

Sunlightweld -

AuthorPosts

- You must be logged in to reply to this topic.

Google hit with record EU fine over Shopping service

Google hit with record EU fine over Shopping service  Business booming for giant cargo planes

Business booming for giant cargo planes  Trump-Putin: The understandable story

Trump-Putin: The understandable story